Introduction to Industrial Use Spiral Door, how much is the price of the High speed Spiral Door?

Industrial Use Spiral DoorIt is a professional industrial door equipment with high wind resistance, high sealing and long service life, which adopts cemented carbide door panel and turbine drive technology.,widely used innew energy,automobile,cold store,medicine,airport and other industries。The following is to introduce the Industrial Use Spiral Door:

1、Brief introduction of Industrial Use Spiral Door

Industrial Use Spiral DoorAlso known as hard turbine door, industrial hard speed door or turbine lifting speed door, it is an automatic door body driven by motor, driven by turbine reel to quickly lift the hard door panel, and guided by unique track structure.。

Industrial Use Spiral Door

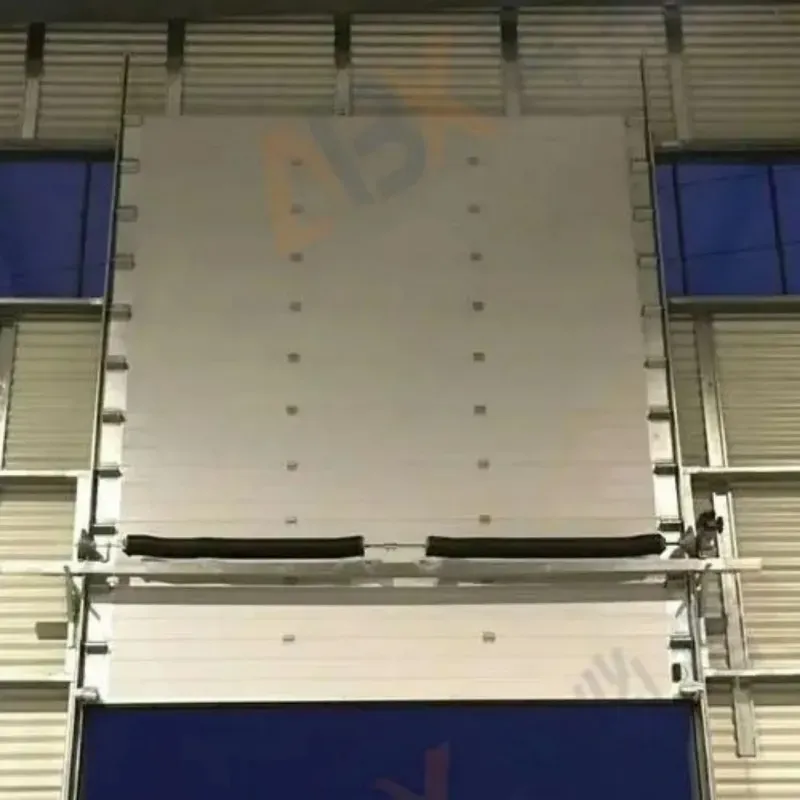

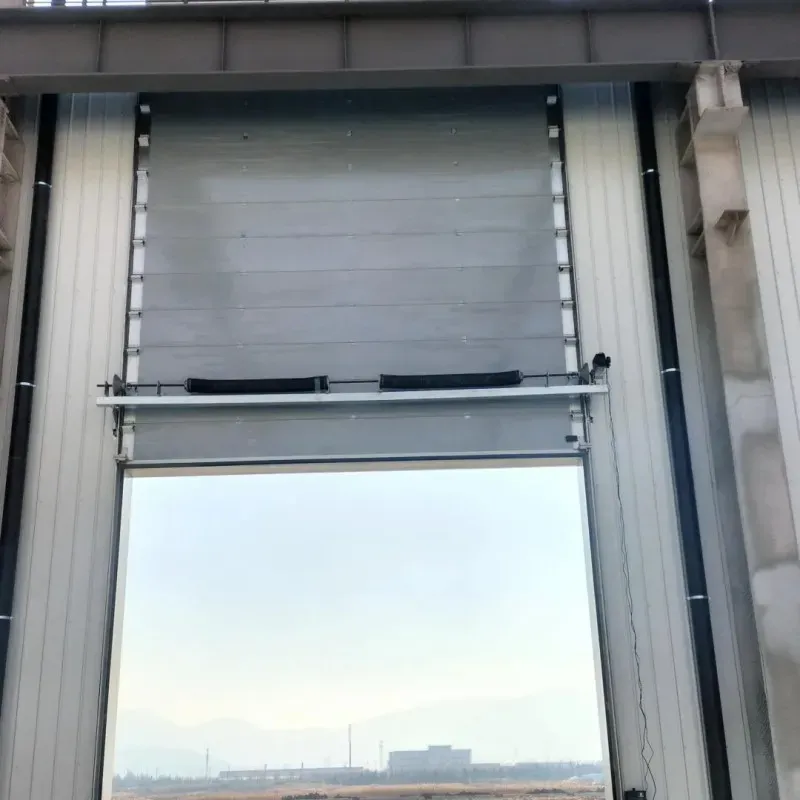

2、Industrial Use Spiral Door HD picture

HD picture of Anbixin Industrial Use Spiral Door,High-speed and efficient opening and closing。

Industrial Use Spiral Door

Note: All the pictures in this article were taken by Anbixin door industry manufacturer.。

3、Industrial Use Spiral Door advantage

Industrial Use Spiral Doors have the following advantages.

- Excellent sealing performance

- Intelligent and convenient control

- Quick opening and closing

- Good thermal insulation

- Modern and beautiful appearance

The edge and middle of the door panel are equipped with EPDM rubber strip, which, together with the tight structural design, effectively blocks dust, wind and rain, insects and peculiar smell, keeps the indoor environment clean, and provides a strong guarantee for industries that require high cleanliness, such as food processing and electronic manufacturing.

Equipped with advanced intelligent control system, it supports remote control, automatic induction (such as radar induction, geomagnetic induction) and other opening modes, and can also be linked with access control, PLC and other systems, which can be flexibly adjusted according to the needs of different scenes, with simple operation and improved traffic convenience and management efficiency.

Ultra-high-speed opening and closing, meeting the requirements of high frequency and high efficiency, and improving work efficiency.

The interior is filled with polyurethane foam material, and the broken bridge design blocks indoor and outdoor heat conduction, effectively maintaining indoor temperature stability, reducing energy consumption of air conditioning and heating, and achieving remarkable energy saving effect in cold storage and constant temperature workshop.

The door body has various colors, besides the primary colors of aluminum alloy, it can also be customized in colors such as sky blue, pearl white, China red, etc. The surface is pressed with stripes, which is simple and generous, and can enhance the overall image of the building and adapt to various architectural styles.

Industrial Use Spiral Door

4、Industrial Use Spiral Door application

Industrial Use Spiral Doors have the following purposes.

- Medical aseptic workshop

- Cold storage area

- New energy battery factory building

- Airport freight passage

- High-end automobile production line

Tightly sealed and insulated, to prevent air convection pollution, to maintain a sterile environment in the workshop, in line with pharmaceutical production standards.

Good thermal insulation performance, reducing cold loss, fast opening and closing to reduce cold loss when opening the door, saving energy.

Stable wind resistance, sealing and dust isolation, providing a stable environment for the production of new energy batteries and ensuring product quality.

Resist bad weather such as strong wind, pass quickly and efficiently, and meet the frequent transportation needs of airport freight.

Ultra-high-speed opening and closing match the rhythm of automobile production, which is firm and impact-resistant, ensuring the efficient operation of the production line.

Industrial Use Spiral Door

5、Industrial Use Spiral Door structure composition

The Industrial Use Spiral Door structure is introduced as follows:

- leak tight structure

- Turbine orbit

- Door panel structure

- Security component

- Drive system

EPDM rubber strip is installed at the edge and middle of the door panel, and an elastic sealing device is installed at the bottom of the door, which tightly fits when closed to ensure excellent sealing performance.

Unique circular arc turbine track system, the door panel runs in the track, reducing friction, running smoothly and with low noise, and prolonging service life.

It is made of aluminum alloy, filled with high-density polyurethane foam, and striped on the surface, which has high strength, heat preservation and aesthetics.

Double-screen induction and emergency stop buttons are standard, and some of them are equipped with airbags, wire rope breakage protection, etc., to ensure safe operation in all directions and prevent accidents.

The combination of high-performance motor and drive system, with encoder, provides strong power, realizes high-speed opening and closing, and accurately controls the position of door panel.

Industrial Use Spiral Door

6、Industrial Use Spiral Door principle

The Industrial Use Spiral Door has the following principles.

- Turbine guide

- Sealing and heat preservation

- Turbine orbit

- Fast drive

- Sealing and heat preservation

Unique turbine circular arc track system, the pulleys on both sides of the door panel roll in the track. When the motor drives the door panel to move, the turbine track provides guidance and support for the door panel, which reduces the friction of the door panel during operation, realizes smooth and high-speed opening and closing, and reduces the running noise.

EPDM rubber strip is installed at the edge and middle of the door panel, and an elastic sealing device is installed at the bottom of the door. When the door body is closed, the rubber strip and the sealing device are closely attached to the door frame to form a good sealing structure, which effectively blocks indoor and outdoor heat transfer, and at the same time blocks dust and noise, thus maintaining the indoor environment stability.

The unique turbine track system is adopted, and the door panel runs in the turbine track. This kind of track system can make the door panel open and close more smoothly, and at the same time, it can effectively reduce the friction between the door panel and the track, reduce the noise and prolong the service life of the door.

Equipped with high-performance motor and drive system, it can provide powerful power and make the door open and close quickly in a short time. Generally, the opening speed can reach about 1-2 meters per second, which meets the requirements of some places with high traffic efficiency, such as logistics warehouses and factory workshops. ?

EPDM rubber strip is installed at the edge and middle of the door panel, and an elastic sealing device is installed at the bottom of the door. When the door body is closed, the rubber strip and the sealing device are closely attached to the door frame to form a good sealing structure, which effectively blocks indoor and outdoor heat transfer, and at the same time blocks dust and noise, thus maintaining the indoor environment stability.

Industrial Use Spiral Door

Industrial Use Spiral Doorit is widely used in new energy, automobile, medicine, cold store and airport,is a popular Industrial Use Spiral Door,The overall structural design is simple and novel.,it has the structure of Cold storage area, High-end automobile production line, Medical aseptic workshop, New energy battery factory building and Airport freight passage。

相关推荐

-

Introduction to Heavy-duty broken bridge Sectional Door, Sectional Door advantages, characteristics and principles

2025-6-16 -

What is a Industrial standard Vertical Lift Door? How much is the price of the Vertical Lift Door?

2025-6-16 -

What is a Heavy-duty corner Vertical Lift Door? Introduction to the principle of Vertical Lift Door structure

2025-6-16 -

Introduction to Industrial park segmental Vertical Lift Door and Vertical Lift Door structure principle

2025-6-16 -

What is a Entrance stacking door for garages? Introduction to the advantages and characteristics of Stacking Rapid Door functions

2025-6-16 -

What is a Fast stacking door stacking door? Introduction to the Working Principle of Stacking Rapid Door

2025-6-16 -

Introduction to Electric multi-segment Garage Door and Garage Door working principle

2025-6-16 -

What is a Cold storage explosion-proof Sectional Door? Sectional Door specifications, models, and parameters

2025-6-16 -

Introduction to Workshop Windproof Spiral Door and High speed Spiral Door advantages and features

2025-6-16 -

Introduction to Cold Chain High-Speed Door , High-Speed Door specifications, model parameters

2025-6-16